A Planar Tensegrity Pipe Crawler

A Planar Tensegrity Pipe Crawler A Planar Tensegrity Pipe Crawler

A Planar Tensegrity Pipe CrawlerHome | Overview | Experimental Hardware

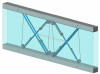

The dual stage tensegrity cross shown in Figure 1 is a feasibility study for the use of a tensegrity structures as load carrying actuators that are capable of “crawling” along an enclosed pipe. The dual stage tensegrity cross is the planar version of the three dimensional shell class tensegrity structure which is presented in the next section. The “crawling” sequence defined on the following page is conceptually identical to the three dimensional version. The three dimensional version would allow for “crawling” down enclosures that have curvature and turns in the path. This is due to the fact that the three dimensional version has more freedom in the achievable reconfigurations of geometry.

Fig. 1. CAD drawing of structure.

Fig. 1. CAD drawing of structure.

Tendon control for this study is accomplished using Shape Memory Alloy (SMA). Shape Memory Alloy has the following important property: maximum recovery force up to 600 Mpa at 4% change in length. This allows for the control of tendon lengths thus making the tensegrity cross structure crawl back and forth inside a threaded pipe. The SMA strings will be activated by sending an electric current from an external current supply source to heat up the tendon and make it shrink up to 4% from its original length. The change in length of the SMA string will effect the distance between the two structures. When the SMA tendons are in the relaxation state, the bias spring will help reposition the two structures to their normal equilibrium shape. The following figure describes the tendon actuation algorithm.

Actuator moving scheme:

The following photos show the current hardware experiment on the above concepts. The structure itself is made from very light weight fiberglass tubing and machined plastic and acrylic parts.